Products & Services

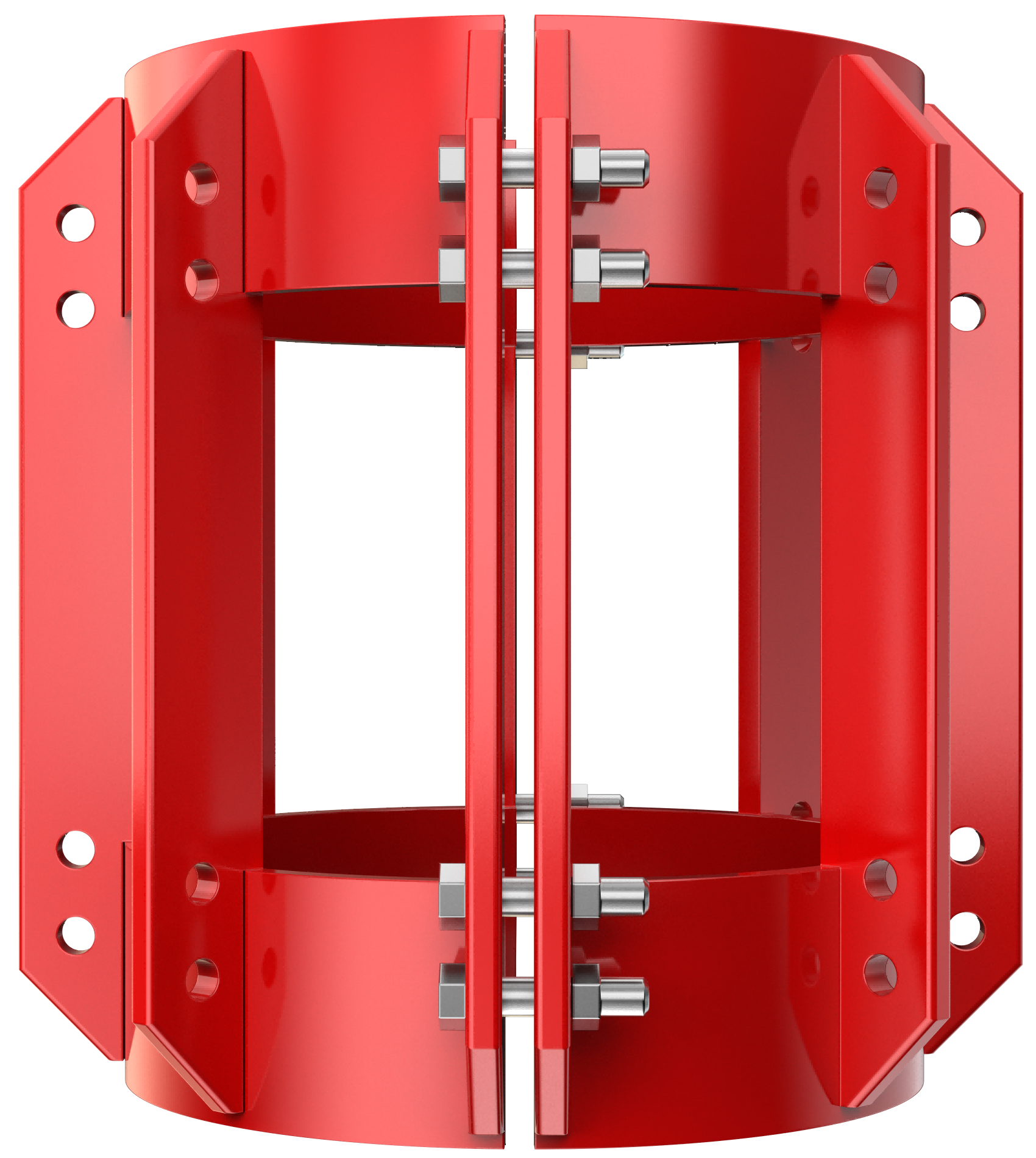

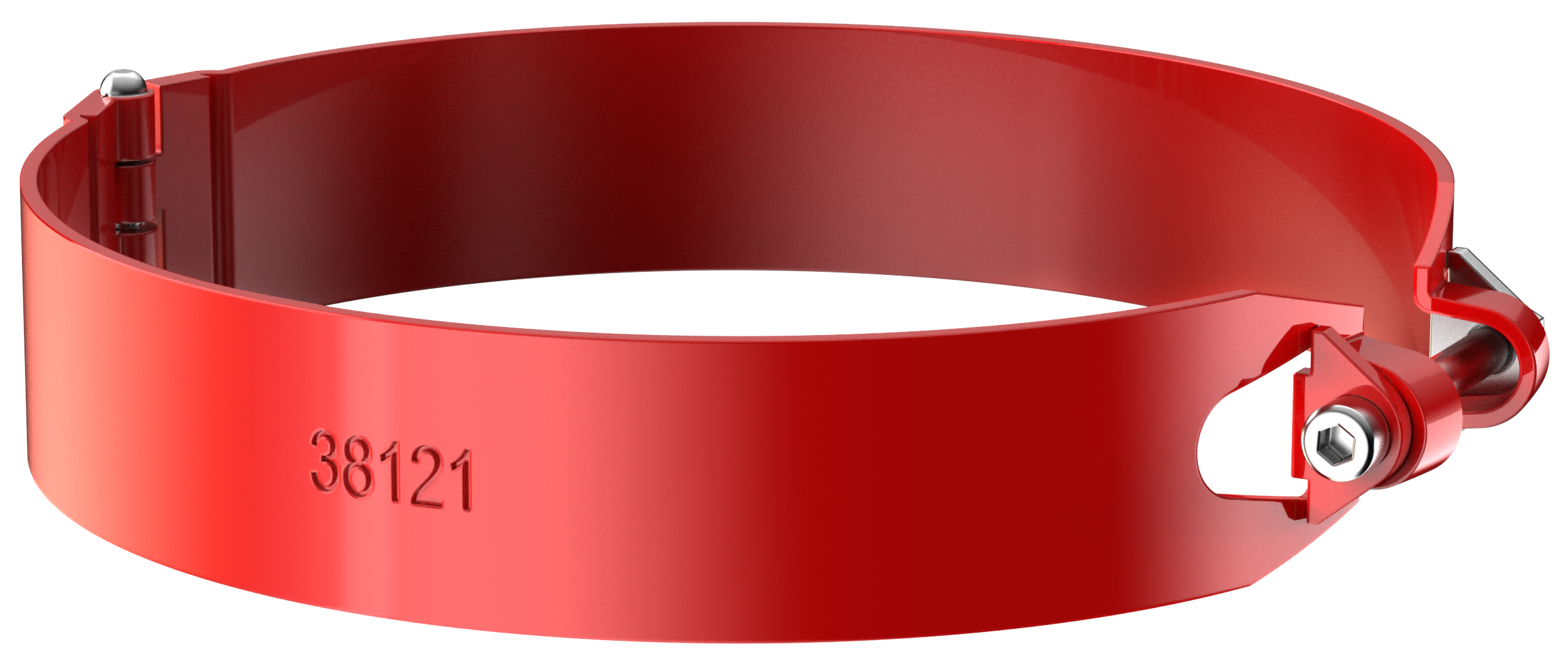

Casing & Cementing

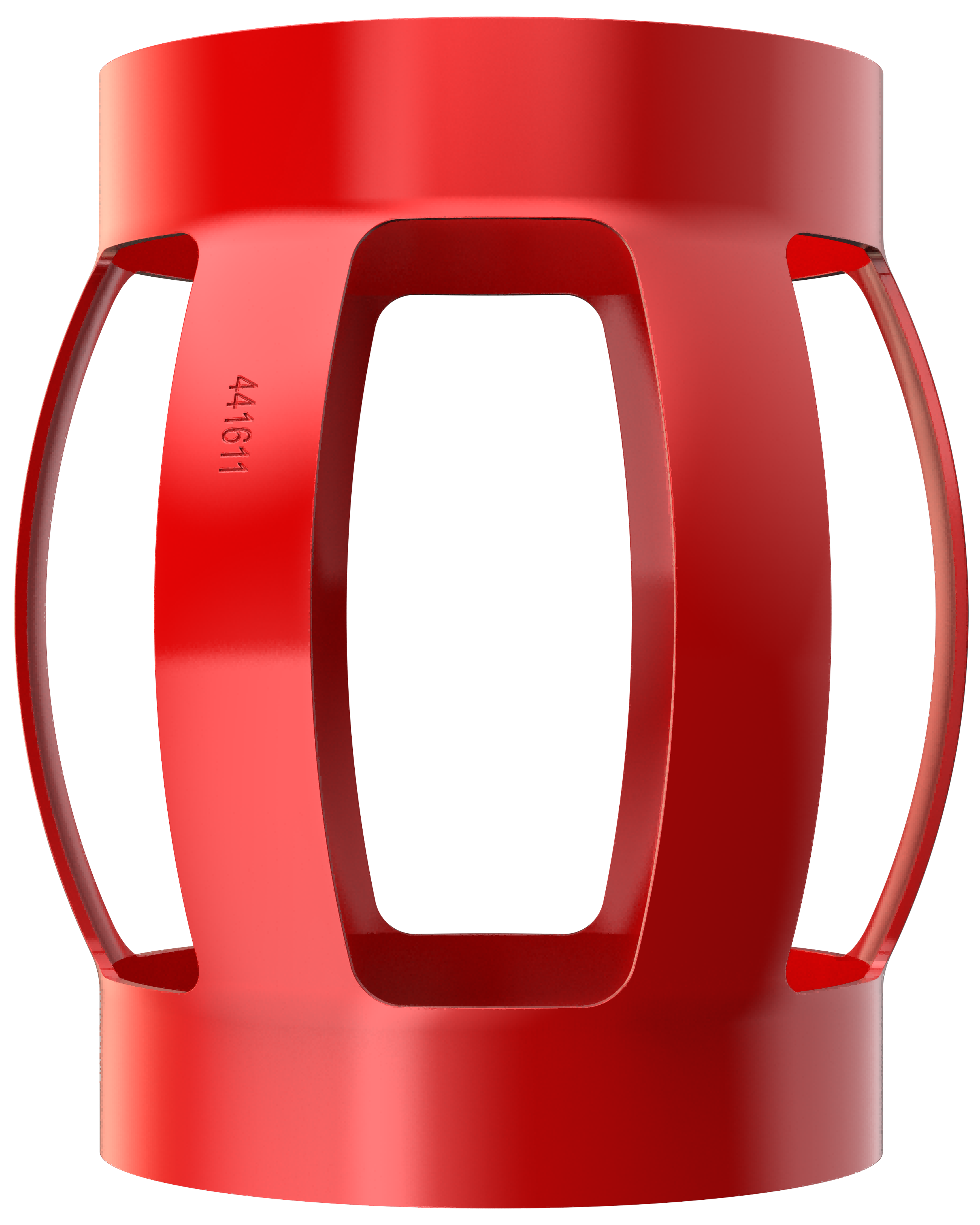

Under Reamed

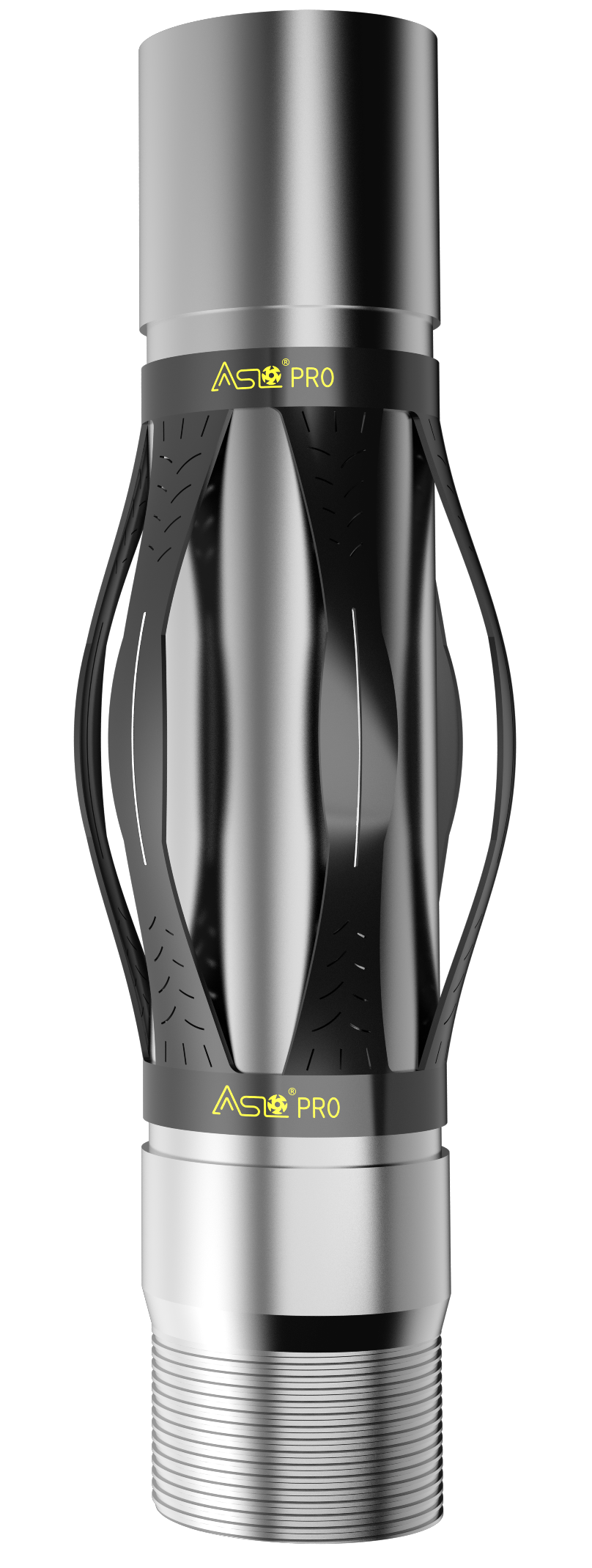

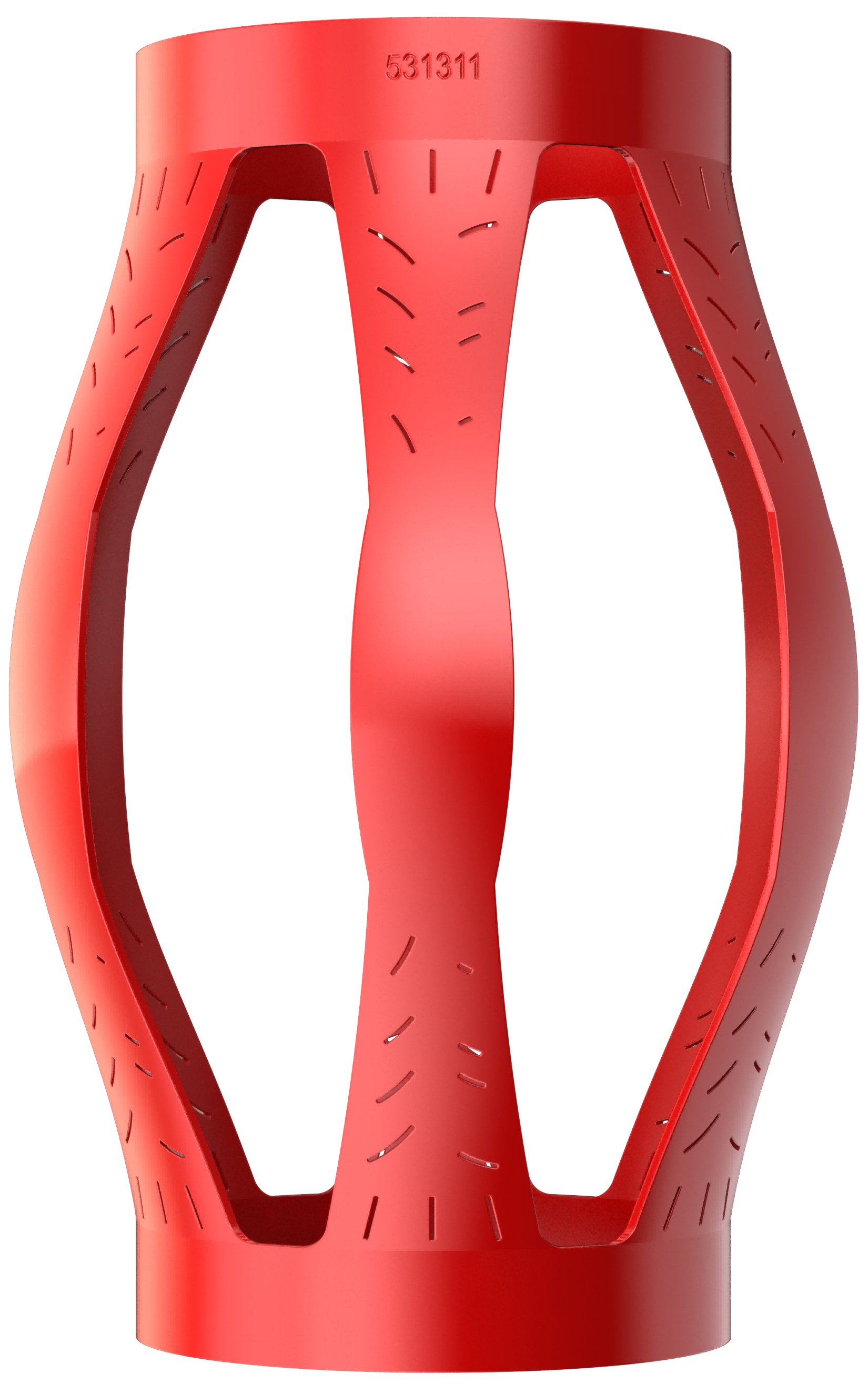

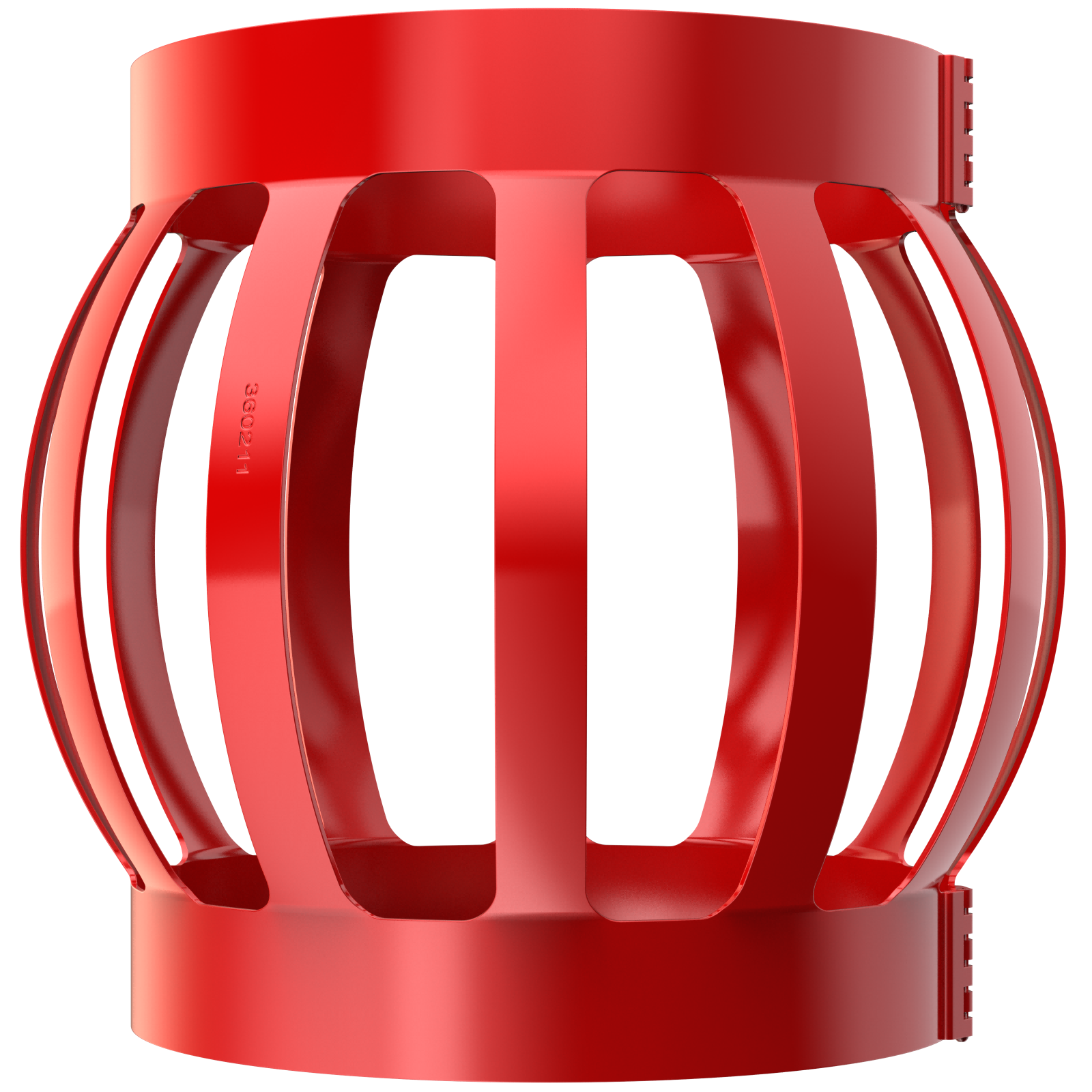

Spring

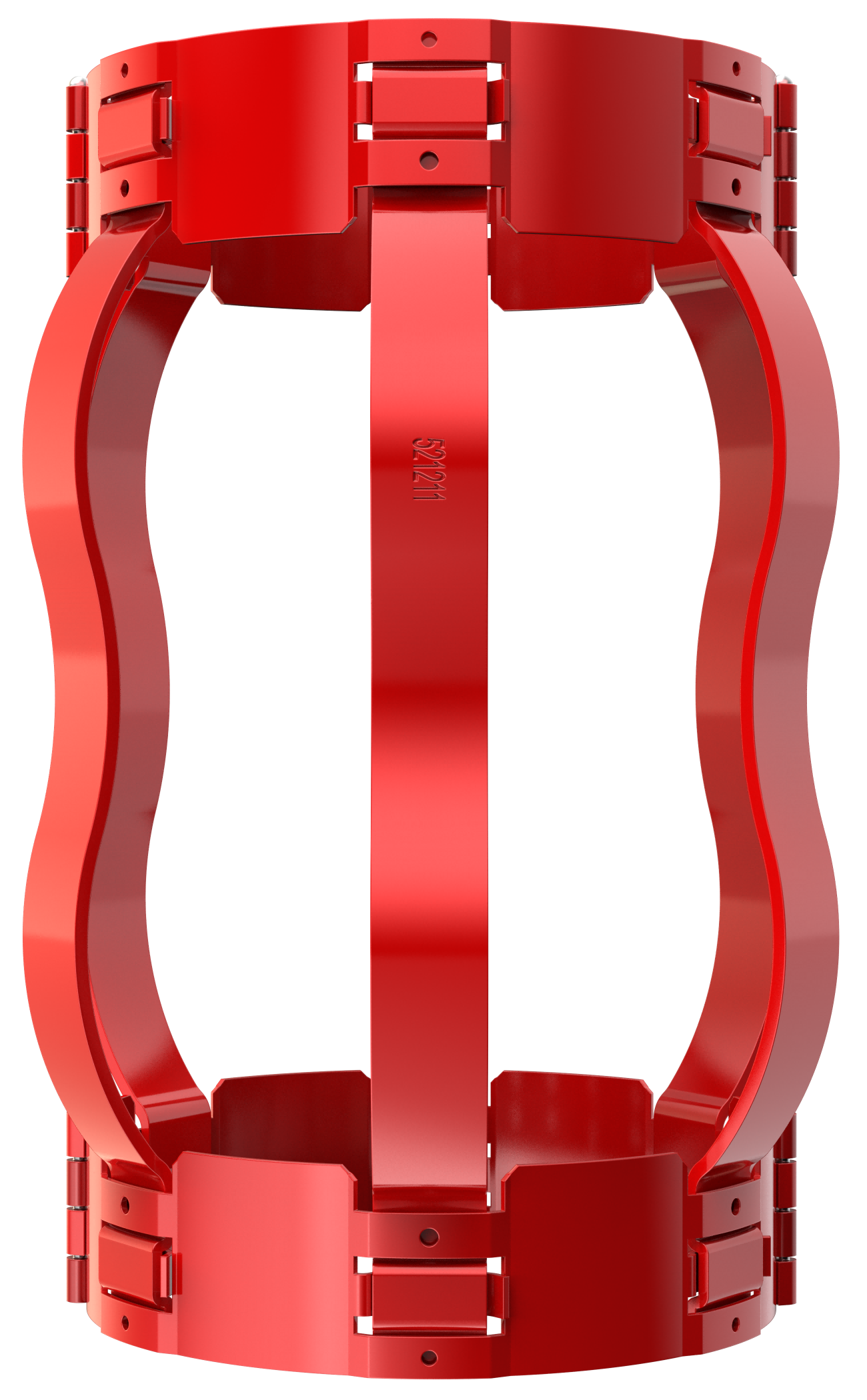

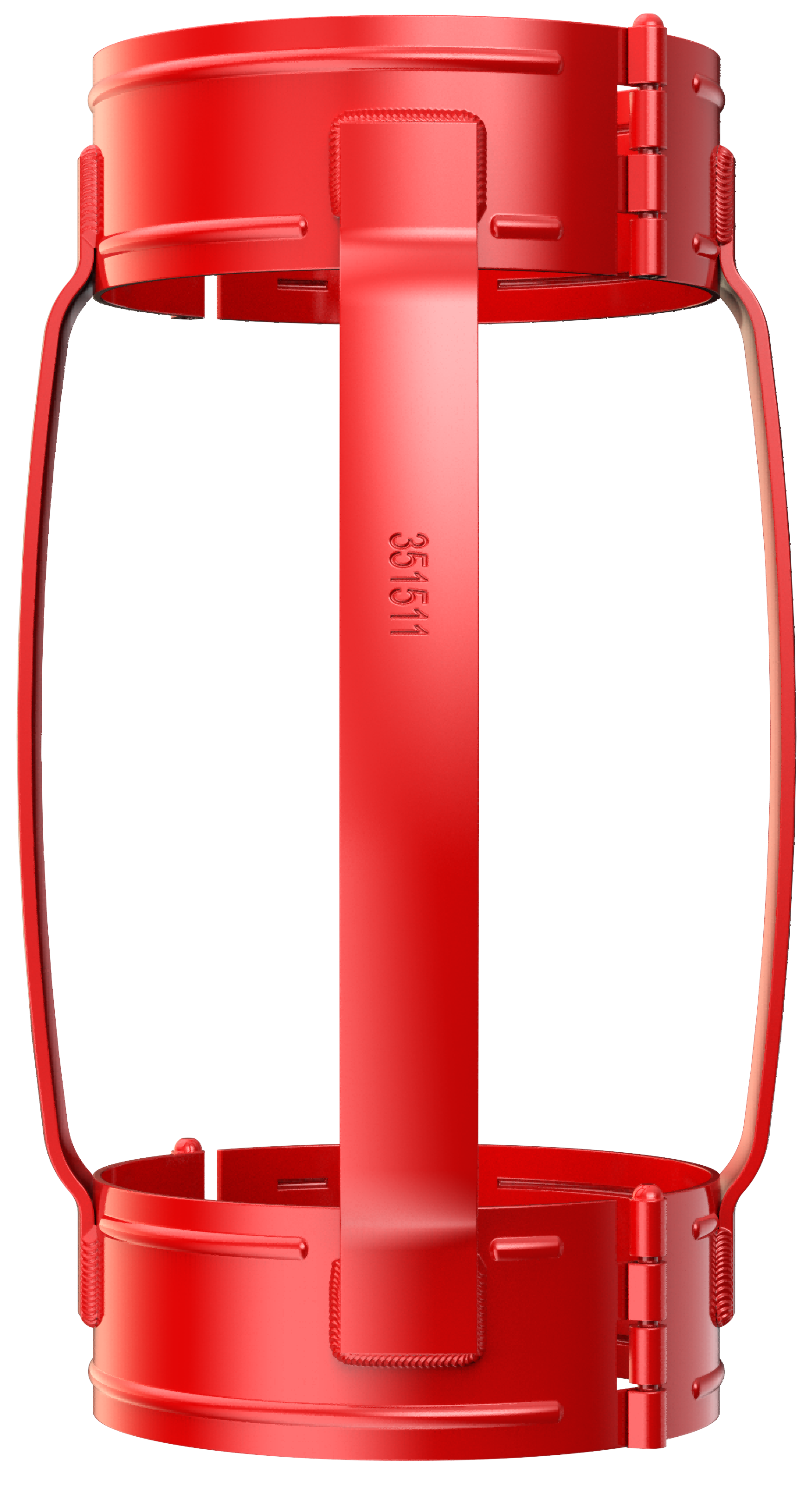

Stop Collar

Anti-Slip Solutions

Exclusive distributor for SAFEGUARD® Technology in Malaysia

Anti-Slip Step Covers

Workers are just one slip away from a serious accident. Our Step Covers are easily installed over existing steps, ensuring a safer environment by covering the leading edge with superior anti-slip material.

Anti-Slip Walkway and Ramp Covers

For injury-free operations and emergency preparedness, our safety covers turn platforms, decks, catwalks, ramps, and any flat area into safer non-skid zones.

Anti-Slip Ladder Rung Covers

Proven performers in the world's toughest environments, we designed Safeguard Ladder Rung Covers to provide dependable anti-slip protection.

Anti-Slip Pipe & Cable Covers

Eliminate slips, trips, and falls caused by exposed wires, cables, pipes, and conduit with Safeguard Hi-Traction® pipe & cable covers.

Heat-Traction™ Anti-Slip Covers

Skip the shoveling this winter and melt ice and snow with Safeguard Heat-Traction™ heated step and walkway covers.

Anti-Slip Mat-Traction™ Mats

Our anti-slip Mat-Traction™ mats are a portable solution to help prevent slips and falls in industrial and commercial settings.

Roll-Traction®

Create a secure anti-slip area quickly by unrolling our heavy-duty, flexible, polymeric geomembrane on walkways, decks, flooring, and more.

Anti-Slip Direct Gritting

When a cover isn't practical, we offer our Hi-Traction® direct gritting anti-slip surface bonded directly to a supplied material.

Anti-Slip Tape

Reduce downtime caused by slip-and-fall injuries with our line of anti-slip tape. Available in a variety of grits and color combinations.

Anti-Slip Pipe Bridges

Prevent costly slips and falls on pipe stock and irregular surfaces with a temporary solution.

Exclusive Malaysian Distributor

We are proud to be the exclusive distributor for SAFEGUARD® Technology anti-slip solutions in Malaysia. Our premium products are designed to prevent accidents and improve workplace safety in challenging environments across various industries.

Visit SAFEGUARD® TechnologyCrane Services

Load Testing Services

Professional Crane Services Partner

We provide comprehensive crane maintenance, parts supply, and certification services through Markisa Services. Our experienced team ensures your crane operations remain safe, efficient, and compliant with all regulatory standards.

Visit Markisa Services